Who needs a membrane autopsy?

When your system shows:

- Rapid differential pressure increase

- Declining flux despite repeated cleanings

- Short runs after CIP

- Unexplained water quality deviations

…a membrane autopsy provides clarity.

Audience: RO/NF operators, food & beverage, pharma, utilities, OEMs – anyone facing costly downtime or premature element replacement.

What you get with EMI Twente

Our standard autopsy package includes:

1. Receipt and documentation

Upon arrival, the module is photographed, labelled, and documented. Key information such as module type, application history, operating parameters, and reported issues is recorded.

2. External inspection

We examine the module housing, end caps, potting material, and external seals for signs of mechanical stress, leakage, biofilm formation, or chemical attack. Observations are documented with high-resolution images.

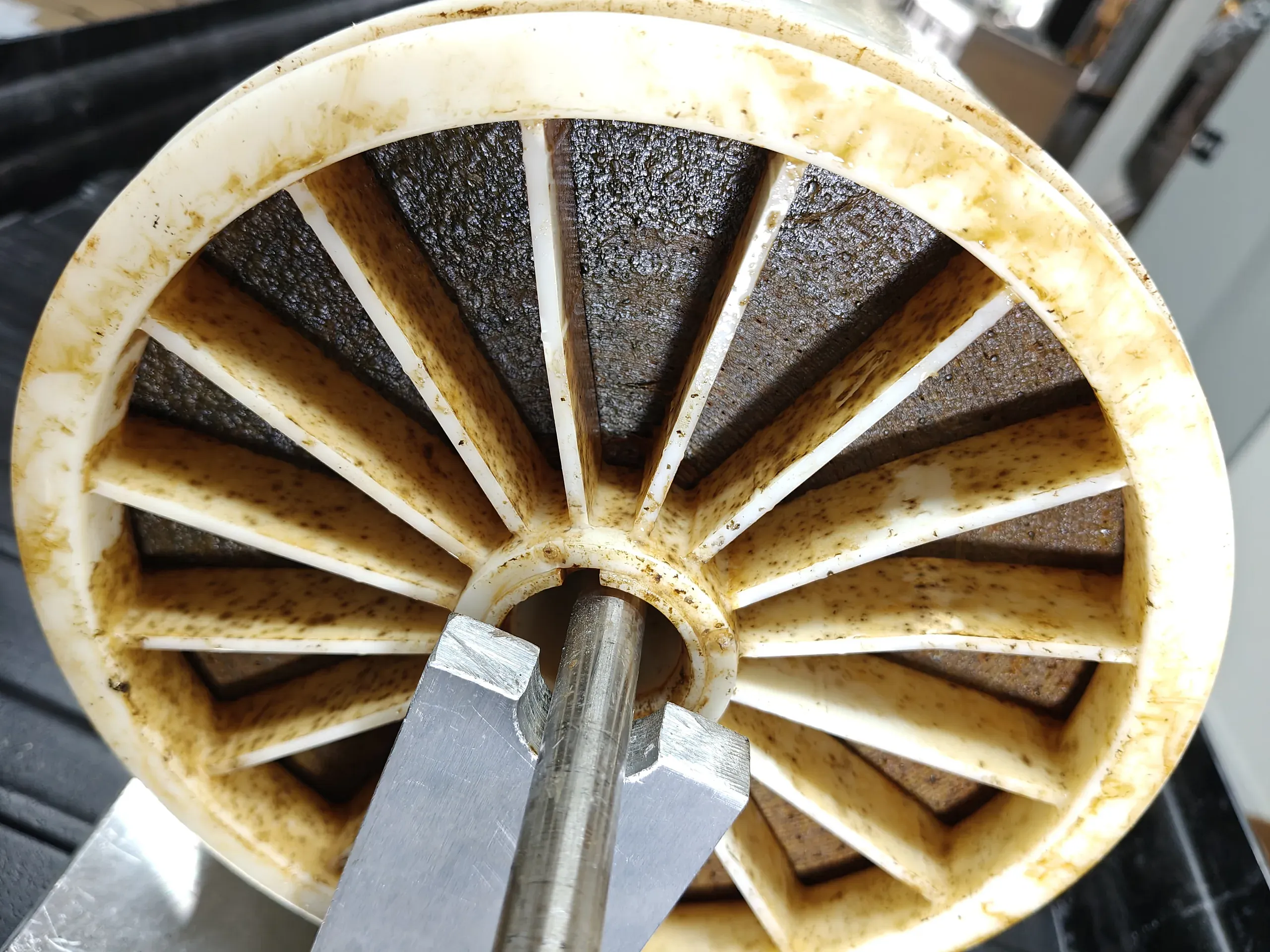

3. Opening and internal inspection

The module is carefully opened using appropriate cutting or disassembly tools to preserve sample integrity. Internal components such as feed spacers, permeate carriers, and membrane leaves or fibers are inspected for mechanical damage, fouling deposits, scaling, or delamination.

4. Membrane surface analysis (SEM-EDX)

Representative membrane samples are analyzed using scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy (SEM-EDX) to characterize the morphology and elemental composition of surface deposits.

5. Reporting

Findings are compiled in a slidedeck including photographs, SEM-EDX analysis, and a description of observed issues with potential contributing factors and how to mitigate these. Based on the initial outcomes, we together decide on next steps.

How it works

1. Intake call (15–20 min) – we review your operating data and symptoms

2. Shipping – you send us the element using our packaging guide

3. Analysis – we perform full autopsy and laboratory tests

4. Report & results call – within 7–10 working days you receive a clear report and action plan

After the initial package, we can do a deep-dive to further answer any remaining questions. With our experience and our large toolbox available we could look into:

Membrane performance testing (e.g. permeability, rejection)

Fourier-transform infrared spectroscopy (FTIR) for organic foulants

Inductively coupled plasma optical emission spectroscopy (ICP-OES) for inorganic scaling

Fujiwara test for residual halogenated compounds

Surface charge measurements (zeta potential)

Pore size measurements (e.g. gas–liquid porometry)

Frequently Asked Questions

When is an autopsy better than “just another cleaning”?

When elements re-foul quickly, ΔP increases rapidly, or standard CIP stops working.

Do you also analyse UF/MF or hollow fiber membranes?

Yes. We regularly dissect spiral wound, hollow fiber, and flat sheet formats. Even ceramic elements are possible.

How many elements should I send?

One element is usually sufficient, but we advise more for representative results in large systems, such as first or second stage elements

Can you also test new CIP protocols or pilot solutions after autopsy?

Yes – we can connect findings directly to cleaning trials or pilot design studies.

What data should I provide beforehand?

There’s no requirement, but operating logs (feed, concentrate, permeate), SDI, ΔP trends, temperature, cleaning history can help us to understand better what has happened to your membrane module.